September 2023

By Pete Maddicks and Tony Howard

Saturday September the 9th was the fund AGM. I am pleased to say that 29 members made it. On behalf of all the trustees thank you all for your support, it is most appreciated.

This month work is continuing on several fronts, we have been working on the superheater header, and regulator box to test them to 300psi. I am pleased to say that the header has passed, the regulator box is almost ready, and should be ready for testing early next month. Work is continuing on the fireman’s side tank. The chimney is making progress and we hope to have it back soon. Anyway that is enough from me so over to Tony.

Saturday 2nd September

Kevin S, Simon B, Steve M and Pete M on site today.

Steve got a second coat of green on the box clack valve covers. Kevin, and Simon welded the extension pipe on the end of the driver’s side water overflow pipe, I fitted the hose adapter, and it then got a couple of coat of red oxide. Kevin, and Simon then rolled the flanges for the main steam pipe stuffing boxes to the same profile as the smoke box. Tony H, and his younger lady called in so he could show her what he is getting up every Saturday, Monday!

Monday 4th September

Bob L, Charles L, Dave Mc. Peter M, Steve T, Tony H.

Charles, Steve and Tony worked on removing the failed rivets from the previous Tuesday riveting session. The 'Steam Fountain ' was temporarily fitted ready for the large copper pipework to commence.

Tuesday 5th September

This session of riveting the tanks, all the bottom angle were completed except the curved part and all the top angle were completed.

Monday 11th September

Charles L, Dave Mc, Peter M, Steve T, Tony H.

Arrived on site to find the Fruit D had been shunted in the week and a lot of components were all over the floor.

After tidying up Charles and Steve made a start on riveting the beading on the bunker, using the fixture that Charles had designed a number of years ago specifically for this task. As they are 6mm diameter rivets they can be fitted using a hydraulic ram.

Tony sorted out the 12mm nuts and bolts from the 10mm ones, then joined by Peter they re fitted the baffles and stretchers inside the water tank,bolting up every other hole ready for the next session of riveting. Tony fitted the overflow pipe complete with its hose attachment to the 10mm injector. Dave and Tony looked at what else was needed to get the superheater header hydraulically tested. It just needed six collars to secure the blanking off plates. Tony found a short piece of pipe and cut off the collars needed.

Saturday 16th September

Simon B, Steve M, Tony H.

Steve was giving the round headed bolts on the running plate a coat of Rustoleum. Simon and Tony took the rough edges off the collars (spacers) that cut on the bandsaw last Monday.

Monday 18th September

Bob L, Charles L, Dave Mc, Peter M,Phil H, Si B, Steve T, Tony H .

Today's job, preparing the superheater header for a hydraulic test. Checked that all the blanking plates were in position and clamped down. Then attach the flexible hose and the pump also the cut off valve.

The superheater header was filled with water and the final two blanking plates were clamped down.

We started to pump the water but two of the blanking plates started to leak.

We decided to re machine the four large blanking plates so they were a better fit and had another attempt. We got more pressure this time but more leaks appeared. We will have another attempt next week.

Saturday 23rd September

Simon B, Kevin S, Steve M, Si B, and Pete M on site today. Dave Mc, and his brother Mike called in for a look around. Dave also dropped off some flanges that Kevin company had made for us. Steve had a very exciting day, he was giving the bolts on running plate a second coat of red oxide.

Simon, Kevin, and Pete first put the supper heater header on top of four pallets, and then drained the water out. Pete collected the bronze cones from the GUV and shot blasted them.

Si, as a loco inspector spent the morning doing a PTS and rules exam, he then joined us on the supper heater header. By the end of the day we had lapped in the four bronze rings, and the twelve blanks for the supper heater elements. We then bolted it all up tight with red stag “B” on all of the joints. It was then ready to be tested on Monday. Tony H, Steve T and their better half’s had afternoon tea on the train.

Monday 25th September

Bob L, Peter M, Phil H, Si B, Steve T, Tony H.

We gave the superheater header another squeeze, and nearly got it to the pressure required when water started to appear from around the studs. So released the pressure and then removed the studs. The threaded part that screws into the superheater were given a coat of Stag B jointing paste and securely refitted. We then had an early lunch to give the Stag time to set. After lunch we gave the superheater header another squeeze and got it to the required pressure, 300 psi. A couple of the blanking plates started to seep a little, but were tightened a little more and the pressure remained constant. The boilersmith came to check that there were no leaks on the superheater header casting itself and was passed fit to use. We then removed all the blanking plates along with clamps, and put them into storage boxes for use on the next Great Western superheater header that needs a hydraulic test. The mating faces were cleaned and greased.

The next item for hydraulic testing is the regulator box. We may have to make a blanking plate if we cannot find one, also new studs will be required along with the appropriate gaskets. A good day all round.

Saturday 30th September

Peter M, Steve M, Tony H.

Job today was preparing the Regulator box for hydraulic testing. Firstly removed the remaining gasket material that was firmly attached, especially around the studs. We lifted the Regulator box into the bosch and got lots of the de-greasing fluid all over. With appropriate scrapers the stubborn pieces of gasket were removed. A rubber gasket was made and fitted and the front cover plate was bolted on. Attention was turned to the back plate. We found a blanking plate. Again we made a rubber gasket and the blanking plate was bolted down. We then had to fit the blanking plates that we used last week to seal off where the main steam pipes are attached. It was difficult as they need to be upright to get a good seal. It will need three to four strong individuals to manoeuvre this heavy item, so we will have another attempt on Monday.

Kevin and Simon setting up the rollers ready to roll the flanges for the steam pipes as they go into the smokebox. Kevin had not used rollers for 25 years, but he soon got back into it!

The finished result, as you can see it looks quite a small radius, but fits the smokebox profile perfectly.

The loco out of the shed and this time in the sun! This time was to allow GWR corridor composite 1146 to go into the paint shop.

The safety valve bonnet in place, we thought that is the safest place to keep it.

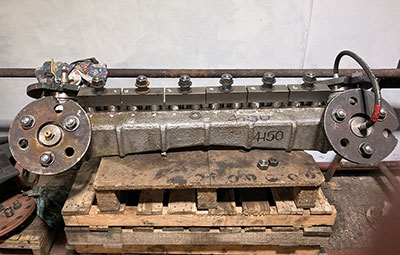

The superheater header all ready to be tested on the following Monday.

Steve T keeping a close eye on the pressure gauge as it closes in on 300psi, this is the test pressure that component must achieve. The test pressure is one and half times the working pressure of the boiler.

Phil D, the SVR boilersmith and boilershop Forman, is seen looking closely to see if there is any leak from what could be the start of a crack.

Monday Steve having afternoon tea on the train, dose he go to bed in his cap!