September 2021 update

September has carried on as August left off. Monday the 6th found Charles L. and Steve T. drilling out the old split pins out of the pony truck A frame. Phil H. and Tony H. were removing the slide plates from the top of the pony frame. I was removing a little damage on the fireman side driving wheel horn face, that had been damaged by a foreign body that had got in.

I have an appeal to all reading this update, would you like to work on the loco? Do not worry if you do not have any engineering skills, we can always find you a job, but if you do have engineering skills there is plenty for you to do to. Whilst the loco is in bits we have to clean, paint the frames and wheels. If you can wield a paintbrush please come along to Bridgnorth, we work on the loco frames on a Monday and Saturday and the boiler on Mondays and Fridays, you will be made most welcome. Give me a ring if you want more information on 07860 504162, or email on petermadd59@hotmail.com There is always plenty of tea and biscuits!

Saturday 11th. What a great day, Simon B. Kevin S. Tony H. and myself cleaned down the pony truck A frame and got a coat of red oxide on. Steve M. was cleaning the pony wheels. Tony and I stripped off and cleaned the brass rubbing plates.

Petal and co. fitted new brake blocks on 7714 in the morning and then came to strip the dirt and old paint off the leading driving wheels.

Monday 13th. Bob L. Got the first coat of chassis black on the A frame and on one of the pony wheels. Steve T. and Charles L. moved the bench grinder to a better place, then Charles put 4150 on our wooden tool box and moved it to the jacks. We can now leave tools, paint etc. where we are working and not have to take it back to the van every day. The box, which is on iron wheels came from Brintons carpets a long time ago. Steve and I cleaned the fireman’s side frames and got a coat of chassis back on. Charles then made a start on cleaning down the leading driving wheels. All this time Tony H. was cleaning parts in the bosh, there is always more parts to clean. Tony and I looked at the spring hanger bolts. They are scrap and must be replaced. I have arranged with the SVR for the right grade of steel to make new ones.

Saturday 19th. this was the Saturday of the autumn steam gala, but as the shed was not open to the public we could carry on as normal. Steve M was getting the first coat of chassis back on the pony truck wheel set, Simon B and Tony H were cleaning off the old paint off the leading driving wheels. I cleaned down the drivers side frames ready for painting.

Sunday 20th. Steve M. and Dave M. carried on cleaning down the leading driving wheels.

Monday 21st. What a day, 9 working on the loco today, Peter D. working on the boiler, Simon B, Charles L, Steve T, and John K working on the driving wheels.

Bob L and one of the loco shed volunteers whose name I did not get, sorry sir, were painting the frames. Tony H. was refitting the brass slide blocks back on the top pony truck casting. I carried on cleaning down the driving site frames, I then removed the top bar of the radial truck and moved the springs to the back ready for them to be removed. This is so the frame stretcher can be riveted in. Peter D. Phil D. and I looked at the cab roof and bunker, so we could come up with a plan to finish off the riveting. The cab roof only requires 8-5/8” rivets and it will be ready for the painters to get up to topcoat. The bunker still need 24-1/2” and 10-5/8” rivets. It also requires some construction holes to be welding up.

Saturday 25th. Steve M. was getting a coat of red oxide on the leading coupled wheels, Colin C. and Neil C. where cleaning the old paint off the driving wheels. Welcome gentleman, we hope we will see you both again soon. Simon B. and Tony H. where working on the bunker, the three holes in the water space that we found last week needed welding up, we use them to help us put the bunker together. Next, the holes that the balance pipes are bolted on to, did not quite line up, they had to be filed square. It was also noticed that the holes that hold down the bunker were too small. Therefore the boys got out the mag drill and made a start on drilling them out. By the end of the day ten left to do. I was working out which oil pads we need to order and cleaned more parts.

Monday 27th. started with us being a little down on numbers but five is pretty good for a Monday. We all had a turn on the needle gun, as you can only do 15 minutes each these days. Bob L. was getting the second coat of chassis black on all sorts of bits and pieces. Pete W. and Steve T. Were working on cleaning the next set of wheels. Tony H. fitted the the split pins in the pony truck A frame then cleaning more parts. I cleaned two of the main driving springs.

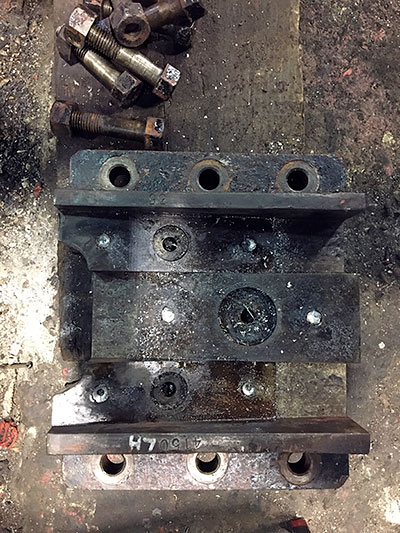

The first set of slide blocks from the fireman’s side of the pony truck ready for drilling out. They have been damaged by water getting in and the oil ways being blocked.

The heads of the screw have been drilled off and the plates removed.

The plates after being removed, they are more complicated than we first thought. New steel will be ordered and new ones made on the milling machine.

The top half of the slide blocks are brass and are in good condition. After a good clean and the oil ways unblocked they are ready to go back on.

Tony H. cleaning the slide blocks in the cleaning bosh.

The pony A frame in red oxide.

The leading coupled wheel with its first coat of red oxide.

Just to show that I do occasionally do some work. Your writer needle gunning the back of the left driving wheel.