September update

By Pete Maddicks

Well, we have had our AGM and it was a little strange, all carried out by phone and email! But at least we are both up to date and legal. What strange times we are living in.

We were allowed back to work on Saturday 5th of September to carry out some H&S jobs. Can I say that the fall from height incident did not involve a working member of the fund, but as a result of the site inspection, we have a number of small jobs to improve the H&S on site, which we have carried out. Two ladders that did not comply, have been cut up, the steps up to the van have been secured to it, the handrail was straightened by Tony, Charles, Phil and Martin. It was then painted a lovely shade of yellow! By Dave. See photo. We have also helped out our friends, working on Warwickshire, we straightened the handrail on the steps up to their van. All of the groups are doing their bit to get the site up to the latest standard, so we can all get back to work, safely, as soon as possible.

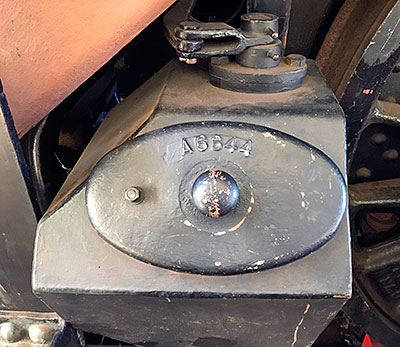

Work at Bridgnorth has been progressing, the ash pan is now fully welded together, the original hinges and one door have been sent to the boiler shop from Bewdley. The regulator rod has been requested and we are going to have to work out how to get it there, as it is 18’ long! But first we have to get it ready to go, Martin, helped by Kevin, has welded up the corroded area where the steam gland is situated in the cab, so it is ready to go to Bridgnorth for machining. Charles has been making a wooden pattern for the special glass for the cab windows. Martin has made a new bracket for the cylinder lubrication Y splitter, that fits on the petticoat in the smoke box. Tony and Martin have put the cab doors on, this has made the cab a safe place to work. Phil has made two new pins for the brake rigging and fitted the rear sand box covers. Tony and Charles have fitted all the castle nuts and split pins on the slide bars. I have fitted the swab box on the driver's side and the oil pot. Tony has ordered two special bolts so I can fit the fireman side.

The next job was to tidy up the van and container. I started on it and got help from all the team, well we were at it all of the first day and at the end of it looked more of a mess than when we started! But in the next session we have found the floor!

The steps up to the van after repair and painting, what a shade of yellow!

The drivers side cab door. You can see from the finish, you can see the photographer.

One of the two rear sand box lids fitted.

The two new brake pins made by Phil.

Lubricator Y splitter fitted to its new bracket, made by Martin.

The swob box and oil pot on the drives side.