October 2024 update

By Pete Maddicks and Tony Howard

Work this month has concentrated mostly on getting the driver's side tank completed. I am pleased to say that it is almost ready for the painters. Work has also been ongoing on the cladding. We also managed to get the loco on the pit, so we could get a few of the jobs left to do underneath completed.

Saturday 6th October

Ðave Mc, Jacob L, Kevin S, Phil D, Simon B, Steve M, Tony H.

Phil welded a few more of the baffles and stretchers inside the tank. The clearance holes for the bolts in the internal splasher were opened up where needed using a die grinder. Once the welds had cooled paint was applied. The frame where the tank will sit was given another coat of chassis black. The blanking off plates were found along with the appropriate bolts, nuts and washers for the front and rear balance pipes, in readiness for water testing the tank in a few week's time.

Monday 7th October.

Bob L, Charles L, Dave L, Dave Mc, Peter D, Peter M, Phil H, Steve T, Tony H.

The Beading that fits on the top of the tank needed some restoration work done as it was water damaged. This was rectified by building it up with weld. The heat from welding has caused it to bend out of shape. This was rectified by using the hydraulic press and trial and error and eventually we got it back to its correct shape. The cladding that fits over the front corners of the firebox, known as 'elephant's ears' was worked on to make sure they fitted correctly. The Smokebox door was checked to make sure it was air tight. This meant scraping lots of paint off the smokebox that had been applied over the years to protect from rust. Eventually, we were satisfied the door was pretty well air tight, just a small area to have more work done.

Saturday 12th October.

No work today.

Monday 14th October.

Charles L, Dave L, Peter D, Peter M, Steve T, Tony H.

The modified frame for the drop grate operating mechanism was fitted to the cab floor plate. Further work was done on the smokebox door to get an airtight seal.

Work was done on the firebox cladding around the 'elephant's ears '. More painting on the inside of the right-hand water tank.

Saturday 19th October.

No work today.

Monday 21st October

Bob L, Dave L, Dave Mc, Peter D, Peter M, Steve T, Tony H.

Work was done on the firebox cladding, and final painting inside the right-hand tank.

Saturday 26th October.

Dave Mc, Jack K, Jacob L, Peter M, Simon B, Si B, Steve M, Tony H.

At last the loco has been shunted over the pit, so the new spring hanger bolts were fitted to the radial truck. The long small diameter vacuum pipe was re fitted.

Meanwhile in the boilershop the water tank was stood upright, and the overflow pipe was fitted. The two top plates were placed In position for bolting down and seam welding. We had the same problem as we had with the previous tank, the fixing holes not lining up so distortion from welding. We eventually got the plates to sit correctly and they were tack welded to the top of the tank.

Sunday 27th October

Dave Mc, Jack K, Richard O.

All top plates welded on the tank. Ashpan door tack welded in position.

Monday 28th October.

Bob L, Charles L, Dave L, Dave Mc, Jacob L, Peter D, Peter M, Steve T, Tony H.

The vacuum retaining valve, flexible hose was attached to the vacuum pump, train pipe, and reservoir.

More work on firebox cladding, and painting on the inside panels of the water tank. The front sandbox control lever along with the brackets that fix it to the right-hand tank were retrieved from storage and were prepared for painting.

A new sign has been put up outside the mess room, I think that this sums up railways and the staff perfectly!

Dave L using the plasma cutter to cut a new piece of the cladding for the front corner of the firebox on the driver’s side.

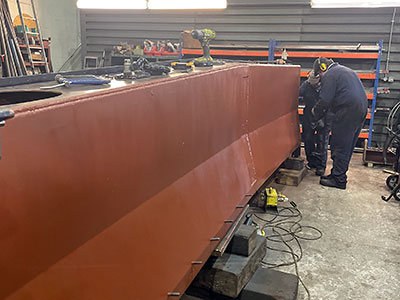

Monday Steve, Peter D, Bob L, and Dave Mc next to the driver’s side tank. They have just finished all the painting ready for it to be stood up for the top to go on.

This is the best photo I could get of the new spring hanger in place.

The flexible pipes that join the vacuum pump, train pipe, and reservoir to the vacuum retaining valve, all connected up. As you can see there is not a great deal of room to work!

Back of the tank with an all over coat of Rustum. At the cab end Tony and Jacob are sorting out the fixing brackets for the front sander operating lever.