November 2022 update

by Pete Maddicks

I have now made two short visits to Bridgnorth to see how the boys are getting on, but I am still not able to do much at the moment. Tony has again done the update this month, therefore a big thank you to him.

5th November

Simon B, Tony H. Just the two of us today. The boiler shop was closed, so no work was done on taking the bunker off the Isle of Man frames. We took a further look at the alteration needed on the vacuum pipe on 4150. We think we know how to achieve this alteration.

Monday 7th November

Charles L, Dave Mc, Peter D, Steve T, Tony H. Various jobs done in the boiler shop. Extracting more countersunk screws from the Isle of man bunker. Linishing boiler tubes for another narrow gauge rail locomotive. We then found another six countersunk screws in the coal space of the bunker. These were buried under compacted coal dust. Probably need to burn or drill out.

Saturday 12th November

Kevin S, Simon B, Si B, Tony H. Jack K (full time staff, boiler shop) Kevin and Simon were in the firebox taking turns beading over the boiler tubes. Tony was at the other end in the smoke box checking that the tubes were not moving. After lunch they carried on the same operation until 3pm when Si and Jack took over.

The bunker that we had been trying to remove from the Isle of man loco frames had been taken off. The screws had been burnt out.

Monday 14th November

Charles L, Dave Mc, Phil H, Peter D, Steve T, Tony H. And a welcome return of Peter M. Charles, Dave and Peter D were working in the boiler shop. Charles and Dave linishing the frames of the Isle of man loco, Peter was working on the boiler. Phil, Steve, and Tony were fitting the last two pressure relief valves. This needed the rear cylinder cladding removed. We found we didn't need to remove it completely to finish the job. We needed a large open ended spanner 4" A/F. Tony eventually found one, and the driver's side was fitted and cylinder cladding re fitted. The fireman's side was a little more problematic as the size across the flats was a little larger. Looks like we will have to file to size next week.

Saturday 19th November

No work today. Boiler shop is closed, and very little to do on the loco at the moment.

Monday 21st November

Charles L, Dave Mc, Peter D, Steve T, Tony H. Dave and Peter were working in the boiler shop, cleaning up the Isle of man loco frames. When they joined the rest of us Dave asked if we knew where the regulator box was as the full time staff wanted to check it over. It was found at the back of the fruit D along with a cover plate. This piece of equipment is very heavy. Tony and Steve ran a die nut down all of the 3/4" Whitworth studs to clean the years of greasy dirt and some damage to the threads. After lunch we got the regulator box into the shed. Charles, Dave and Peter carried on working in the boiler shop beading over boiler tubes and a bit more work on the Isle of man loco. Steve and Tony finished filing the flats on the pressure relief valve so the spanner will fit, they then fitted this valve and refitted the cladding. We also put the refurbished regulator rod in safe storage.

Wednesday 23rd November

Extra working day. Dave Mc, Jack K. Boiler shop apprentice. More bolts tubes beaded over. You can see Jack working on 4150's Boiler on the latest SVR Video.

Saturday 26th November

No work today as Boiler shop was closed. Nothing can be done on the loco until the boiler is reunited with the frames.

Monday 28th November

Charles L, Dave Mc, Peter D, Peter M, Phil H, Steve T, Tony H. Charles, Dave, and Peter D were working in the boiler shop. Charles was angle grinding the bunker of the Isle of man loco. Dave. Peter D, and Steve T were working on beading over boiler tubes along with Jack K. Phil and Tony were looking at where it could be possible to fit a low level filler for the water tanks. They fitted the breather pipe to the bunker and looked the possibility of fitting the filler pipe underneath the bunker and pipework inside the bunker and fill the three water tanks via the breather pipe. After a long Discussion it was decided against this method. Peter D then came up with another method of achieving this aim. All of this because it may be against working at height regulations in the future for footplate crew to climb up onto the tanks or tenders.

The frames of the loco waiting in the shed for the boiler to go in, we can then start on the copper pipework.

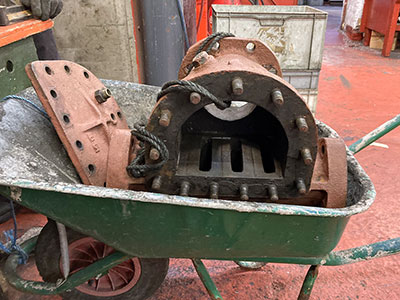

The regulator box and cover in the machine shop waiting to be refurbished.

The steam fountain and some of the parts to go on in the yellow box. On the right is the regulator valve, this also requires refurbishment.

The funds fruit D van with the new sheet ready for the winter.

The recent SVR video “inside the Bridgnorth boiler shop” includes shots of Jack the apprentice working in our firebox.