November 2018 Restoration Update

We're pleased to report that the boiler is now inside the boiler shop at Bridgnorth and being worked on, initially largely by 4150 Fund volunteers. Stay removal and needle-gunning of the inside of the barrel are the first priorities. At Bewdley, we are concentrating on cab roof alignment, pipework which doesn't require attachment to the boiler, and cab floor construction.

Newly fabricated sand delivery pipes, the rear pipes being the two on the right. The front sand boxes are mounted 'inboard' between the loco frames, making the delivery pipes (on the left) longer and with more complex bends.

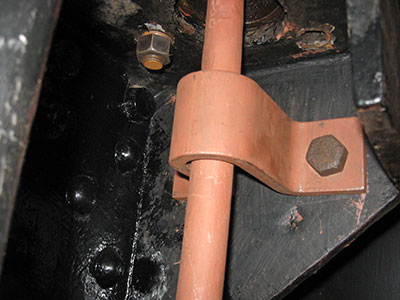

The new driver's side rear sand delivery pipe in position.

The four lower corners of the cab roof were badly corroded and have been cut out. These are two of them.

New sections have been welded in, this one being the driver's side rear.

New handbrake end-stop bracket, flame-cut from solid. It limits the travel of the handbrake operating rod, and is subject to considerable stress judging by the distortion in the old one.

The two lower coal plates, separating the coal and water spaces, have been welded into the new bunker. The upper coal plate will be welded in place once the filters and water feed pipes from the base of the bunker to the water valves have been installed. Photos: John Whitcomb.

Our boiler being moved into the boiler shop at Bridgnorth on 30th October. Photo: Dave McFall

Work is continuing on the removal of steel stays from the firebox. (For those not familiar with boilers, the stays are lengths of round bar, threaded at both ends, which separate the outer steel firebox wrapper from the inner copper firebox, thus creating a water space surrounding the fire.) Photo: Peter Willoughby.