March 2024 update

The good news this month is that the fireman’s side tank is in the final stages of assembly, with just the back and top to weld on, the top beading to rivet in place and the filler to weld on. Then we can start on the drivers side. Hopefully this will be a lot quicker as we can use all of the techniques that we learned on the first one. If you can get to Bridgnorth on the Saturday of the open house weekend, you will be able to come and see the progress and have a chat with one of the team.

Saturday 2nd March.

Kevin S, Peter M, Steve M, Tony H.

Today's job was to get the six superheater elements from the container and into the shed ready for hydraulic testing. These are brand new elements and we purchased them from Tyseley loco works a number of years ago when a batch were being made and we added to the order.

Monday 4th March.

Bob L, Charles L, Dave Mc, Peter M, Steve T.

The water gauge was brought into the boiler shop, and the four rivets that it sits over were ground flat to get a waterproof seal.

The front back plate was removed so further welding could be done.

With this back plate removed we fitted the large vertical pipe. A air tool grinder was used to remove many coats of Rustoleum and welding that was fouling the the the hole. Once the pipe was fitted into the bottom of the tank and the reinforcing ring we fitted the top plate along with the reinforcing ring. We then marked the pipe ready to be cut off to the correct length. The top of this pipe has to cut at an angle to match the angle that the front the tanks are made. We cut the pipe 1/4" shorter so it can be welded inside the reinforcing ring.

Saturday 9th March.

Bob L, Jack K, Peter M, Simon B, Steve M, Steve T, Tony H.

We were informed on Friday that the hydraulic test on the superheater elements could not be done until the end of April at least. That meant that the elements would have to go back into the container, and also the regulator box as the area where they were stored was needed. First job was to do this. Once done, work carried on in the Boiler shop on the left hand tank ie welding, grinding, and painting.

Monday 11th March.

Charles L, Peter M, Phil H, Steve T,Tony H.

Phil and Tony worked on the new ' stuffing boxes' Steve then spot welded them ready for the next phase of work. Charles, Peter, and Steve carried out more work on the water tank.

Saturday 16th March.

No work today.

Monday 19th March.

Bob L, Charles L, Dave Mc, Gary M, Phil H, Si B, Steve T, Tony H.

Work was done on the main steam pipes and stuffing boxes, as well as fitting the overflow pipe at the front of the left hand water tank. The 3/8" Whitworth screws were welded onto the front back plate, these eight screws hold the internal splasher.

Thursday 21st & Friday 22nd March.

A hydraulic ram was adapted to jam the rivets in the narrow section of the water tank that is in the cab. This method worked very well and a hour each evening this section was finished.

Saturday 23rd March

No work today.

Monday 25th March.

Bob L, Bryn T, Charles L, Dave Mc, Steve T, Tony H.

More work in the boiler shop.

The back of the front back plate was painted and whilst this was drying ,more

rivet holes were prepared for riveting later on in the day. Once the back plate was dry, we bolted it into position. This is ready for final welding. A riveting session was carried out using the hydraulic ram.

The good news is that the Fruit D is now back in place on the re laid siding alongside platform two.

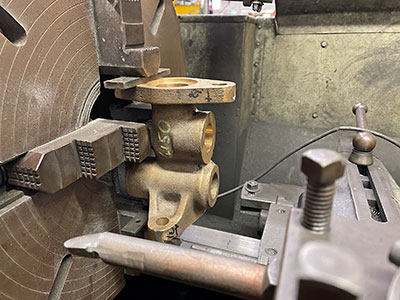

One of the steam heating valves in the lathe for machining.

Simon B cleaning up and putting a slight countersink in ready for riveting.

Steve M polishing the copper cap ready for the chimney to go back on for the open house weekend.

Bob L, aka splash and dash, getting more paint on the tank on the cab end.

Charles L drilling an extra hole for a nut and bolt to pull the bottom of the plate in for welding.

Phil H machining the end of the pipe that will form part of the main steam pipe gland on the smoke box.