June 2025 Update

By Pete Maddicks & Tony Howard.

Monday the 9th June was a momentous day for the fund as in the boilershop the hose pipe was put into the firebox through one of the mud hole doors and water started to flow in. By the close of play, the water was halfway up the firebox, with only a few small leaks. This month we have continued with more excellent progress, the steam fountain has passed its hydraulic test and is all ready to go onto the boiler.

The safety valve was all stripped down for inspection and testing (see 2nd photo). We will temporarily replace the springs with steel pipes and fit the clack valves so they can all be tested when the boiler is hydraulic. Our safety valve and steam fountain were purchased from Swindon all the way back in September 1974. As it was being manufactured 6000, King George V struck a bridge at Llantarnam ripping off the safety valve. The loco was dragged to Ebbw Junction shed just outside Newport for repair. Our valve was dispatched from Swindon, fitted to the King and she made her way back to Hereford, it was then sent back to Swindon and reset from 225 pounds per square inch, to 200 pounds per square inch. Work on the cab floor is well on the way to completion.

Monday 2nd June.

Bob L, Charles L, Dave L, Peter D, Peter M, Phil H, Steve T, and Tony H.

A lot more cladding was painted. Dave bought the wooden elbow rests to fix on the flat surface of each water tank and fixed them on.

It was decided to trial fit the internal splashers to the water tanks. It was a good decision as the holes need opening up. The timber for the cab floor was brought from storage into the shed. Work was done on the boiler and the lubricating pipework for the vacuum pump.

Saturday 7th June.

Jacob L, Kevin S, Peter M, and Tony H.

The two sections of the front large copper balance pipe, were brought into the shed, ready to be temporarily fitted between the two water tanks.

Tony found the nuts and bolts to fix them together. We only used three bolts in the tanks. The bolts were pushed through from the inside. Peter drove the Crane and gently placed the first section in place. Jacob, using a long piece of wood gently pushed the bolts through the flange. A nut was quickly screwed on. The second section was fitted the same way.

The two center flanges did not line up. One was lower than the other. We knew this would happen. Using the Crane we pulled the lower one into the correct position and put the bolts through the two flanges.

The pieces of cladding at the front and rear of the saddle, where the smokebox sits, were removed so the bolts that secure it in place, can be fitted when the boiler is finally installed.

We also helped another group to move two heavy cast iron gate posts.

Monday 9th June.

Charles L, Dave L, Dave Mc, Peter D, Peter M, Steve M and Tony H.

We opened up the holes in the left-hand tank internal splasher. We then trial fitted it and were satisfied with the result. We then fitted the right-hand tank internal splasher. This one required more fettling to be made to fit. After grinding, and removing a couple of millimeters from the bottom it fitted perfectly.

In the Boilershop more work was carried out on the boiler. Eventually it was slowly filled with water, for the first time in sixty years!

There were a few leaks, but nothing serious.

Saturday 14th June.

Peter M, Simon B, Steve M, and Tony H.

Peter, Simon, and Tony got the large cladding sheet that sits on the top of the firebox onto a trolley so Steve could paint the underside. Simon and Tony then altered the two compensating plates on the brake rigging that had been fitted incorrectly.

After lunch, Simon and Tony fitted the front sanding operating mechanism. First Peter fitted the top bracket that supports the operating handle, which is bolted onto the right-hand water tank in the cab. We needed to fit this as it is in three sections and it was at least seven years ago that it was fitted at Bewdley. Before we took it off we marked the positions of the three sections. Unfortunately, these marks were painted over. Anyway we did manage to fit it correctly, and it opened and closed the sand boxes perfectly. Peter also stripped down the safety valve so it could be checked over.

Monday 16th June.

Charles L, Dave L, Dave Mc, Peter D, Peter M, Phil H, Steve T, and Tony H.

The two internal splashers had their final fettling and are ready for painting. The eight pieces of boiler cladding have had the final painting of undercoat and have been moved to safe storage. More items of firebox cladding were moved to the paintshop for final undercoat painting. The safety valve bonnet was checked to see that the fixing bolts lined up to the plate it sits on, a little filing was needed to achieve the correct fit.

The Steam Fountain (manifold) was hydraulically tested and passed.

Saturday 21st June.

Jacob L, Kevin S, Peter M, Steve M, and Tony H.

After fitting the front sand boxes operating mechanism, we took a look if it was fouling anything else on its travels though the whole length of the water tank. We noticed it was fouling a lubricating pipe that had been temporarily fitted last Monday. More concerning was that the flange on the front balance pipe was not sitting correctly against the right-hand tank. This was because we had not fitted all six bolts, only three. The bottom three needed fitting.

As there was nobody thin enough on site to fit through the water filler to get into the water tank to push the final bolts through the flanges, another way to get this done was needed. It was suggested that we take the whole assembly off and start again by pushing all six bolts through the flange in the tank before offering that section of pipe up to the bolts. A long piece of wood was found wide enough to cover all six bolts. This wood was put into the tank via the water filler and using the Crane to support the section of copper pipe it was slowly offered up to the bolts. As each bolt petruded through the flange on the pipe a nut was quickly screwed on. When all nuts were on we tightened them up. We then bolted the second section of pipe the the first. We did the same operation on the left-hand tank, pushing the bolts through the tank just enough to see the ends, and using the Crane slowly lifting the pipe until the holes were in line with the bolts, and using the wood pushed the bolts through the flange and a nut was quickly screwed on and they were all tightened up. We were happy with the outcome and the front balance pipe is now in the correct position, work can continue with the lubricating pipework for the vacuum pump.

Monday 23rd June

Bob L, Charles L Dave L, Dave Mc, Peter D, Peter M, Phil H, Steve T, and Tony H.

Dave L, and Steve T made a start on installing the wooden flooring in the cab. Charles and Tony looked at finishing the steel surround at the base of the Blast Pipe. Firstly this needs to be cut to size and once ready fireclay cement will be put around the blast pipe base. The two halves of the plate will be clammed into place and welded together.

Bob cleaned the paint off the brass window frames that had been painted by mistake. He also painted the internal splashers. Peter D applied more paint to the boiler, and also did more lubricating pipework.

Dave Mc spent quite some time searching for the blanking plates for the superheater elements, ready for hydraulic testing, he eventually found them. Possibly testing pipework and superheater elements next week.

Saturday 28th June.

Dave Mc, Jacob L, Kevin S, Peter M, Steve M and Tony H.

Following a request to move our cab roof from where it has been sitting for a number of weeks, plans were made to put it back onto the loco. This involves shunting loco 813, a large wagon that 82045 tanks were on and 4150, into the yard. Using slings and the Crane, we first turned the cab roof that had been sitting upside-down the right way up. It was brought to the front of the shed by the roller shutter doors it was lifted using the JCB and placed back onto loco and temporarily bolted in place. The loco's and wagon was shunted back into the shed. More painting was done on pipework and inside the frames.

Monday 30th June.

Bob L, Charles L, Dave L, Dave Mc, Peter D, Peter M, Si B, Steve T and Tony H.

Bob did prep work for painting. Dave L and Steve carried on installing the cab floor. The superheater elements were bought out of the container ready for hydraulic testing. Using the blanking off fixture that we found last week we attached it to the ends of the first element. We had to make two rubber sealing washers, and we got the fixture to seal off the ends. We were then told that new superheater elements needed to be tested at 1,000 psi. As there is no pressure gauge on site that will achieve this reading we will have a rethink. We did achieve a reading of 500 psi.

Firebox cladding that had been painted by paintshop staff was removed to safe storage. The large cladding sheet that covers the top of the firebox was moved into the paintshop for the staff to work their magic on it.

The hose is in and water is flowing.

The safety valve dismantled and laid out on a pallet ready for inspection and then testing.

The remains of the safety valve bonnet in the field along side the bridge at Llantarnam. Photo by Derek Short/Monmouthshire Railway Society Collection.

KGV on Ebbw Junction Shed with our safety valve on, all ready to return to Hereford. Photo by Godfrey Crew/Monmouthshire Railway Society Collection.

The backhead showing the small leaks that have now been caulked.

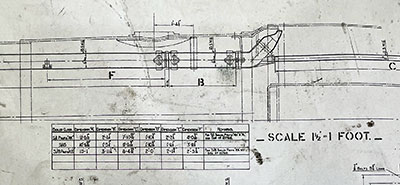

The main steam pipe all ready to be fitted.

Looking down at the boiler, most of which has now had its first coat of heat resistant paint, just the top of the firebox and the bottom of the throat plate left to do.

The balance pipe in place between the tanks. Photo Tony Howard.

1942 drawing showing the layout of the main steam pipe.