June 2023

By Pete Maddicks and Tony Howard

Another month has gone by, we are still making progress towards the day the loco is steamed for the first time. We are still waiting for the tanks to be riveted, but we have been promised, that once 2968’s boiler is in the frames they can go into the boiler shop. We are also in the process of organising the manufacture, and fitting of the larger copper pipe work. We are also planning the repair and fitting of the copper cap on the chimney.

Saturday 3rd June.

Mike H, Peter M, Simon B, Si B, Steve M, Tony H.

The holes for the whistle chain guides in the cab roof were welded up. We will have to drill new ones once the steam fountain is fitted.

We looked to modify the hole in the Smokebox that the last bolt to bolt the chimney down. Looks as though it will be a little awkward. We tried using mounted points, but not very successful. Try again on Monday with a different method.

Monday 5th.

Tony on holiday today so I have stepped into the breach. On site Si B, Charles L, Phil H, Steve T, and Pete M.

Today we had a visit from Peter D. he sustained a back injury several months ago, and has been making a slow recovery, this is the first time he has been over, and we are pleased to say that with luck he will be back with us in two weeks time. Today the shed was shunted to get 75069 out of the paint shop, and put 2968’s tender in. The first job was to check the loco over and then remove the “not to be moved” board. We did not do much on the loco today as she was on the move around the shed for most of the day. We moved more parts into the paint shop and we also got the safety valve bonnet out of the GUV (General Utility Van) for a start on cleaning it up.

Saturday 10th June.

Bob L, Peter M, Tony H.

More beading was painted. The shut off cocks for the lubricating pipework were fitted to the smokebox.

We also helped the team working on 'Dunrobin'

Monday 12th June.

Charles L, Dave Mc, Peter M, Tony H.

All the pipework that was in the container at Bewdley was bought to Bridgnorth. It was sorted into sizes. The larger sizes were put into safe storage while the smaller size was put into the shed alongside the loco. The four holes that were in the Smokebox to secure the spark arrester were blocked off using round headed bolts. One of these bolts had to have it's head modified so the cover over the lubricating pipework would fit.

Another modification that we are making is putting an oil pot on the motion bracket to oil the vacuum pump operating arm. Earlier large Prairies had this oil pot fitted, but later ones this oil pot was moved to a different place making it difficult to oil up. We set up a steel plate to fit the mag drill on. This job should be done on Saturday.

Saturday 17th June.

Kevin S, Simon B, Steve M, Tony H.

The hole was drilled in the motion bracket using the set up we did last Monday.

A start was made on cleaning up the

Pressure relief valve bonnet.

Monday 19th June.

Bob L, Charles L, Dave Mc, Peter M, Steve T, Tony H.

More boiler/firebox bands painted along with cab/bunker beading. A decision was made about the low level water feed. A plan was drawn up on to achieve this and pilot holes were drilled into the water space in the bottom of the bunker.

Saturday 24th June.

Only Steve M here today. He was polishing the brass safety valve bonnet.

Monday 26th June.

Bob L, Bryn T, Charles L, Dave Mc, Phil H, Si B, Steve T, Tony H.

The water pipes that feed water to the water valve's were found along with the filters, bolts and spacers, and flanges. They were all bolted to keep all components together. Pipework for the low level water feed has been obtained, we will need some lengths of pipe to make a start on fitting.

The chimney was lifted off so we could open up the hole that was out of position.

We needed eight more brass flanges for the steam feed to the injectors. The drawing was found and these will be ordered this week.

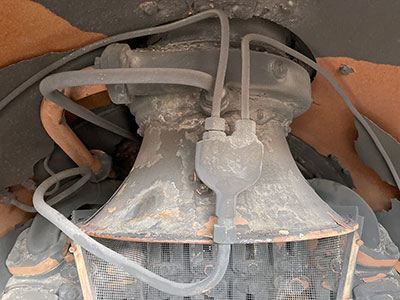

This photo shows the inside of the smokebox of 2857 showing the amount of equipment that has to go in. You can see what a lovely clean working environment you find inside the smokebox!

The two oil pots for the vacuum pump mounted on the motion bracket, the one on the right supplies the pump, and the one on the left the pump rod.

On Monday 19th the view from our van was of 2968 boiler having its official steam test, I am pleased to say that it passed.

The view looking down into the bunker, Charles is getting ready to fit the low level fillers. He will not have a great deal of room!