January 2025 Update

By Pete Maddicks & Tony Howard.

Welcome to the first update of 2025.

It is going to be a very important year for railways and the SVR. 200 years of the Stockton and Darlington, 60 years of the SVR, and 53 years of the 4150 Fund!

The first working Saturday of the year we intended to put back on, the cab roof, we arrived at Bridgnorth all ready to start, but the first problem was freezing fog, the second one was the class 14 would not start! We will try again next Saturday. This will be the first time that all the major components have been together since the loco was dismantled an awfully long time ago! Success! The cab roof is on, it was a perfect fit on the bunker, but will require a little adjustment to fit on the tanks. Thank you to all the boys for a great day’s work, and thank you to Will for driving the Ruston.

Monday 6th January.

Bob L, Charles L, Dave L, Dave Mc, Peter M, Steve T, Tony H.

First working day of 2025. The main job today was to get the right-hand tank sitting correctly. It was leaning inwards at the cab end. Using a jack and blocks of wood we got the tank sitting upright. This allowed us to get the remaining fixing bolts in. We then looked at the left-hand tank and did the same operation, though only needed six of the remaining bolts to be fitted.

Saturday 11th January.

Dave Mc, Jacob L, Kevin S, Peter M, Simon B, Steve M, Tony H.

The job that was planned for today was to fit the cab roof temporarily. We would bolt the roof to the bunker first, and that would tell us if the two water tanks were sitting in the correct position. Unfortunately, this job did not go ahead as the class 14 diesel would not start, it was -5 degrees. So two cups of tea/coffee we all went home. Will try again on Monday.

Monday 13th January.

Bob L, Charles L, Dave L, Dave Mc, Peter D, Peter M, Phil H, Steve T, Tony H.

JoNo, the cab roof did not go on. Arrangements have been made for this to go ahead next Saturday.

Jobs done today were the final six bolts were fitted to the right-hand tank. The quadrant that fits under the reversing lever was fitted. Lubricating pipework was made.

A more accurate measurement was made for fitting the supporting bar that fits between the water tanks at the cab end.

The holes will be drilled in the tanks when they are lifted off when the boiler comes out for hydraulic and steam testing.

Saturday 18th January.

Dave Mc, Jacob L, Kevin S, Peter M, Phil H, Si B, Simon B, Steve M, Tony H. Will M (full-time staff)

Will M, driving the Ruston diesel shunter, the loco was shunted out of the shed into the yard. Si B driving the JCB, the cab roof was brought to the loco in the yard, and lifted onto the loco. The rest of the gang started to bolt the cab roof to the bunker as the bunker has had no work done to it, so it should have not moved out of position. It fitted perfectly. The front of the roof bolts to the two water tanks. As the tanks have been riveted, and welded since the cab roof was last fitted, we expected that the holes would not line up exactly. We were right, but with a fair bit of fettling we did get most of the bolts to fit. More work to be done on Monday.

Monday 20th January.

Bob L, Charles L, Dave L, Dave Mc, Peter M, Steve T, Tony H.

More fettling to get the fixing holes in the cab roof to line up with the water tanks. Also, the two angles that sit longways between the cab roof and the tanks needed some work done on them to get get them to sit correctly. Eventually everything fitted to our satisfaction. More parts were painted, and further work was done on the firebox cladding.

Saturday 25th January.

Jacob L, Tony H.

Tony cleaned up the round-headed bolts and nuts that hold the two long angles inside the cab roof. These bolts and nuts had got very rusty over the years. They are now ready to be fitted on Monday.

Monday 27th January.

Bob L, Charles L, Dave L, Dave Mc, Peter D, Peter M, Steve T, Tony H.

The right-hand angle was bolted to the cab roof and welded to the top of the tank. Unfortunately, our welder decided to go on the blink and stop working, so the left-hand angle could not be done.

More parts were painted, and lubricating pipework was made.

One hour after the JCB was started up, the loco is on the way back into the shed, all done.

Jacob cleaning out the paint from the fixing down holes ready for the tank to go back on.

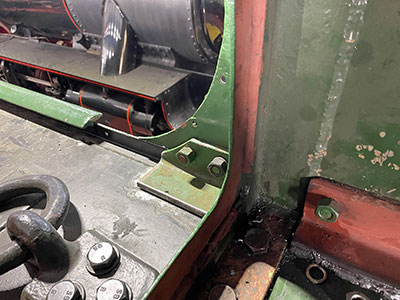

The first angle iron welded on the driver’s side that the cab is bolted to.

The angle iron in front of the window all ready for welding.

Another component brought out of storage ready for testing. On this occasion it is the condensing coil for the lubricator.