February 2023 update

By Pete Maddicks and Tony Howard

Sorry for the update being a little late this month. Unfortunately the loco has spent most of the month out in the yard as the shed was full of locos on winter maintenance and one requiring the wheel drop to investigate hot boxes. This month I am again indebted to Tony Howard for the update.

Saturday 4th February.

Simon B, Tony H.

Just the two of us today.

We were asked to look at the oven door on the Manor's ashpan. We took measurements and made a sketch of the latch also took photos. We also tidied up the the last piece of the backhead cladding.

After lunch we got more of the crinolines out of the safe storage where they have been kept since the loco came to Bridgnorth.

Monday 6th February.

Charles L, Dave Mc, Peter D, Peter M, Phil H, Si B, Steve T, Tony H.

More work on the backhead cladding. This was the bottom part that needed cutting to clear the new drop grate mechanism.

Items were fixed to the firebox. The fruit D had a good clear out and a lot of stuff was got rid of. We did find items that we have been looking for.

Saturday 11th February.

Kevin S, Simon B, Tony H.

We arrived at Bridgnorth today to find the loco outside the shed and over the oil store's pit.

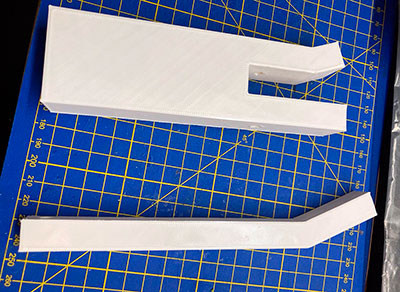

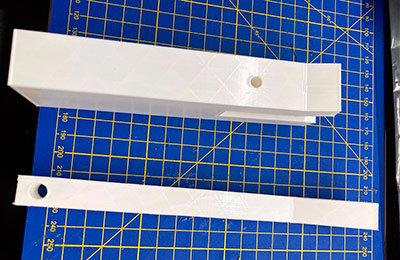

Simon, using the dimensions we had got last week has made a copy of the latch we need on his 3d printer. We retrieved the oven door out of the bunker, and clamped it to the ashpan and got it in the correct position. We marked the piece that needed to be removed. The new latch mechanism will be made at Kevin's place of work.

Monday 13th February.

Bob L, Charles L, Dave Mc, Peter D, Peter M, Steve T, Tony H.

More parts fixed to the firebox. Some of these were new Casting's. The fixing holes have been drilled with very little clearance.

We got an adjustable reamer and opened up the holes. This worked on all except one. This one had to have a drill put through the holes. It was awkward shape to hold in a vice, but the holes were eventually opened up.

Saturday 18th February.

No work today.

Monday 20th February.

Bob L, Bryn T, Charles L, Dave Mc, Peter D, Peter M, Phil H, Steve T, Tony H.

More parts fitted to the firebox. The frame that holds the cover plate over the drop grate mechanism was fitted back onto the footplate. The vacuum pipe that runs vertical from the train pipe to the vacuum brake was trial fitted to see if we would need to alter the above frame. It would soon became apparent we have to make alterations to the vertical pipe.

The steel was cut to make the four long spring hanger bolts that fit to the radial truck.

The brake rod that was bent when fitting the boiler has been repaired and was painted and is ready to refit.

All the parts were found for the water gauge.

Saturday 25th February.

Kevin S, Simon B, Steve M, Tony H.

The ɓrake rod was refitted.

We then turned our attention to the damper door operation mechanism.

The front damper door operating lever looks OK with little modification. The rear one will need a lot more work.

Steve was cleaning the rods that have got a little rust and dirt over the last couple of months.

Monday 27th February.

Bob L, Charles L, Dave Mc, Peter D, Steve M, Steve T.

The blower brass casting that we could not fit last week was returned machined so the 5/8" nuts can now fit without fouling the casting. It is now fitted.

The hinge for the oven door was delivered and trial fitted to the door. It will be welded to the ashpan when the boiler comes out for testing.

Blanking plates were made to seal off the steam passages in the superheater header in readiness for pressure testing.

More painting was done on various parts, and the rods and wheels were given a good clean.