February update

By Pete Maddicks

Friday 4th, an extra day to start off the month. The boys on site today were Dave Mc, Tony H, Peter D, Peter W, Phil H, Gary M and Bob L. It is absolutely magnificent the hours that these gentleman are all putting in at the moment, all are retired except one and he will be very soon! I could not be on site today so thank you to Tony H for the information.

As the loco was due to come off the jacks on Saturday we needed to get the side rods on as it is the easiest place to fit them. This was successfully completed and the reverse eccentric rods were fitted, but there was a problem with the forward ones, therefore Dave Ma and I removed the forward eccentric straps as they will foul the frame stretcher, this was done on the Saturday. Gareth A and I freed up the spring for the radial truck. This spring helps to keep loco straight and stop the loco from swaying.

As it turned out she came off the jacks early on Monday morning, we found the loco in the yard on the concrete pad, she will stay there until Friday lunch time and then be shunted to road four next to our van. We are going to have an extra day on Friday to put the con-rods up as this will be the last chance for quite a while as the shed has got to be ready for the new roof and crane to go up. Charles L filed out some excess white metal from the crossheads, Steve T made new felt pads for them and put them into soak in the oil bath. I made a start on fitting the new slide plates for the pony truck and I was joined by Charles. We found that they needed a little fettling, but we got them to fit. Tony H joined us after lunch and it was found that the counter sinking was not quite deep enough, Tony will do this on Saturday.

Another extra day, Friday 11th. We had an early start today as we only had till lunch time to get the conrods on. The team was Dave Ma, Tony H, Peter D, Phil H, Bob L and myself. After the obligatory cup of tea it was time to get down to the job in hand. With Ollie from the full time staff driving the 08 we soon got the first rod up, the only problem was the felt pad was a little too thick, so it needed a bit of a trim down. We then moved onto the other (fireman’s) side and fitted that one as well, all split pins and retaining bolts were also fitted. All done by 12.45pm and the loco shunted onto road 4. Bob and I had to leave after lunch, both picking up grandchildren from school, but the rest of the boys put on the tarpaulin to protect the loco from the weather. All the rods will need a good clean and a coat of grease to keep the rust away.

Saturday 12th. Steve M made a start on cleaning up the rods that had become rusty as the shed roof leaks quite badly and put a coat of chassis black on the fireman’s side crosshead. Tony H, Kevin S and Simon B. fitted the slide plates on the pony truck. The first job was to deepen the countersinking on the plates. The plates are very hard so this took quite a time. As this was going on Kevin and I had a bit of a tidy up, we put three main springs on each of two pallets. I then made up the flange for the bunker drain with a 3/4” BSP. outlet for Simon B to weld up as home work. We then all got to work on the slide plates, we fitted all the plates, then removed the 1/2” countersunk screws one at a time, putting on Loctite and then screwing them down as tight as possible. We then put the top slide on, but it was a little tight, we therefore have had to file of a few thou. off the sides of the top sliders which are brass. All work well, so another job completed.

Monday, 14th. Today we made a start on the pony truck, Tony H and Dave I. On the fitted bolts that hold on the horn ties, all the bolts were cleaned up and then a die-nut was run down, all the nuts had a tap run through them. Total of eight bolts and sixteen nuts, eight full and eight half nuts. Now there was a problem, the bolts are fitted, which means they are a very tight fit and when they were taken out they were all put in one box, Tony got the Micrometre out, measured them and found that they were different sizes, but eventually all the right bolts were in the right hole.

Charles L. First job for the day was to remove some excess white metal from the pony axle boxes. Charles then found all six of the pins that the springs hang on, on the bottom of the axle boxes. First he had to drill out broken split pins and then clean the rust off. He then cleaned out the holes in the springs. By the end of the day he had completed five out of the six.

Steve T made up the pads for the pony truck axle boxes, he first made the two for the thrust faces, then the four for the horn guides, but the famous Swindon standardisation strikes again! There are two boxes, one left and one right The left one had previously been on two Halls and one other large Prairie, it had round edges. The right box had been on two Castles and a Grange, both boxes had numbers we could not read, this box had square edges. He then made the two for the under keeps and fitted then into the cages, but first he had to fit new springs to the cages.

I cleaned up two old boiler plugs to go into the bottom for the balance pipes, I drilled through and tapped them out to 1/4” BSP., we will now fit small brass valves, so when the loco is put away for the winter the water can be drained out. I ordered the brass valves at 11.30am on the Monday and they were delivered at 11.15am on the Tuesday. Thank you Heritage Steam Supplies, brilliant service.

Saturday 19th. I was not able to be at Bridgnorth, but the boys were in as usual. Dave F-I, Tony H, Simon B, Kevin S and Gareth A, (again thank you to Tony H for the information), they got the axle boxes and under keeps back on the pony truck, then put the A frame back on. This was then followed by the horn tie frame. It all sounds so simple, but it is all very heavy and also there is not a great deal of play, it can be a little awkward to get it all back together. Well done boys, a great job. Thank you to Dave Ma for going over to Tyseley to collect the rubber and steel dampers. Simon had done his homework, the welding on the flange for the bunker drain.

Monday 21st. Good turn out again, Phil H and Tony H were working on the fitted bolts on the pony truck A frame. One was a little tight, so Phil did a little fettling in the lathe. Steve and I reamed out the holes in the springs, that Charles had cleaned up the pins for last week.

Saturday 26th. Not such a good day, first job was to fit the rear guard irons, then we tried to fit the spring under the radial truck, but in the hurry to get off the jacks we had failed to fit the two brackets that the spring bear on, we will have to jack up the rear end to fit them. Petal and co were on site today to fit the springs, the bushes are too tight, we will therefore have a look on Monday and come up with a solution. The team on site were Tony H, Simon B, Kevin S, myself and of course petal and co.

Monday 28th. The problem with the springs was sorted out and Steve T, Charles L, Bob L, and I fitted four, we also fitted three brake blocks. Phil H and Tony H fitted the replacement special bolts to the pony truck, they then went onto repair eccentric sleeves on this job, they were joined by Dave Ma.

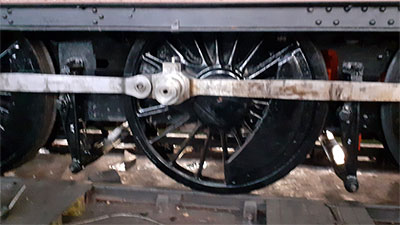

The side rods on. Photo: Tony H.

The con-rods on.

One old and one of the replacements, I think we made the right decision to replace the pony slide plates! Tony H.

The two little brass valves for the bottom of the balance pipes.

The pony truck assembled in the north end of the paint shop. Photo: Tony H.