December 2022 Update

By Pete Maddicks and Tony H

Saturday 3rd December.

Kevin S, Simon B, Tony H.

Beading over the last few boiler tubes in the firebox. All done except for the 3 tubes that moved. We left those for the boilersmith to sort out. The large flue tubes need to be done, another job for the boilersmith to do.

Week commencing 5th December.

Dave Mc and Jack K beaded over the last tubes in the firebox, sorted out the tubes that had moved and beaded over the flue tubes in the firebox and smokebox.

A start was made on beading over the tubes that have to be done on the smokebox. All the tubes in the smokebox except the ones that have been beaded over will have to be expanded.

Saturday 10th and Monday 12th December.

Kevin S, Simon B, Tony H. Beading over the last few boiler tubes.

Monday 19th.

I (Pete) was on site and Tony was not, so I well bring you up to date on what was going on. Dave Mc, Peter D, Charles L, Steve T, Si B and myself on site today. Jack of the of the full time staff was working in the smoke box. He was working on the flanges for the regulator box, blower and vacuum ejector. The first job of the day was to get the loco around to the boiler shop, Si prepared the 08 shunting loco, but the first problem of the day she could not maintain air! After a few attempts this fault was resolved, we think it was ice holding a valve off its seat. With Oily working the signal box and Dave as shunter the loco was worked around to the Hollybush Road siding. Oily then propelled her into to the boiler shop with the Ruston. It was a very tight fit as the loco is 41’ long and the space in the shed was only 44’, but she in as you can see in the photo 3. As this was going on Peter D. was in the fire box finishing off the last few tubes. Charles and Steve were collecting all of the parts for the main steam pipe, they were also getting all the nuts, bolts and wishes together ready for it to be fitted.

The next job was to have a good tidy up around the boiler and remove the staging from in front of the boiler ready for the lift. We then went to the stores to collect the great support brackets and the regular stuffing box. We then fitted the support brackets and I repaired the oil way in the stuffing box gland. We then fitted the stuffing box temporarily and found that the two studs at the bottom are 1/2” to short, so to new ones need to be manufactured. This is the reason we are trial fittings everything so we then know that when we put them on for good there will be nothing to hold us up.

Congratulations to Jack Kerswell on winning a gold medal in the WorldSkills competition. Jack is twenty two and is apprentice in the boilershop and has been working on your boiler from the start. At twenty two he has been teaching us old times how to repair our boiler. It is fantastic that he can pass on what he has learned to our boys that can only be described as being in their golden years. Well done Jack, we are so proud, with the skills that you and the other apprentices are learning the future of steam is looking bright.

Thursday 29th.

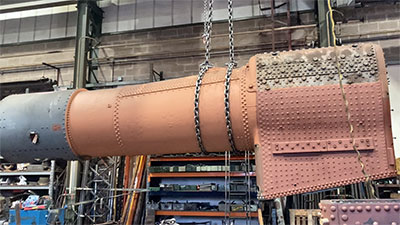

The last working day of the year. On site today in the boiler shop was Phil D, Dave F-I, Dave Mc, Peter D, Kevin S, Charles L, Steve T, Tony H and myself. The first job of the day was to get the ash pan off the top of the fire box and put it on the floor, the next job was to get the large chains onto the 30t crane, you need a crane to lift them so we use the 6t to lift the hook. The boiler was then lifted and turned round and lowered onto the ash pan, they can then be bolted together. As this was going on Kevin, Tony and I had reversed the crank of the drain cocks as it was foul for the brake adjuster when the hand brake was on. The boiler was lowered in, but the clearance is so tight that a few of the stays had to have a 1/8” off the ends. The good news is by the end the day the boiler was in. We had to cut small piece off the corner of the ash pan that was pushing down the brake rigging. We can now do all the pipe work before the boiler comes out of it’s hydraulic and steam test, so we can get the maximum out of the boiler ticket. Well that is another year gone, but the start of a very special year for the Fund, as we are now on the home stretch.

The loco ready for the boiler lift.

The start of the lift, the boiler just off the ground.

The boiler has been turned, the ash pan has been fitted and is on its way to over to the ready to be installed.

All done, the boiler in, it was a long day, but Phil D said that it was one of the easy ones! From left to right, Dave F-I, Phil D and Peter D.

This is the sort of craftsmanship we need if we in the heritage movement is going to survive into the future. Jack won a gold medal for this. Well done Jack, we are all proud of you.

I found this photo in another old box of photos, I think it was taken in the early eighties at Bewdley. My driver, on the left is Vic Smith, or Vic the slip as he is now on the SVR. We are getting 75069 ready for it’s day work. The photo was taken by a colleague from when I worked at Oldham Batteries. Photo Keith Kent.