August 2024 update

By Pete Maddicks and Tony Howard

August has been another busy month, although most of the boys have been away on holiday! The driver's side tank has come on really well with all the riveting on the outside is complete, also the cab end is complete. The copper pipe work is progressing well. We have been moved off the pit so 75069 could use the wheel drop for a spring hanger to be replaced, and then 4930 could have a V&P (valve and piston) exam.

Just a reminder that the AGM is on Saturday September 7th at 2.00pm. It will be held in the nursery building which is behind the Kidderminster Railway Museum on the right of the driveway that leads into the car park.

Saturday 3rd August.

Jacob L, Peter M, Steve M

The loco will have to be shunted off the pit on Monday. So, we needed to be sure it will be fit to move. All loose nuts and bolts were removed off the running plate, to remove the rope that is holding the top of the fire box cladding sheet which is tied to the connecting rod. Jacob oiled up the loco ready for the move. Steve polished the copper cap, and the safety valve bonnet.

Monday 5th August.

Bob L, Dave L, Dave Mc, Jacob L, Peter M, Phil H, Steve T, Tony H.

The shunt took place first thing this morning, with the Standard 4 taking 4150, place on the pit. We are now on the back road in the shed. Despite not having the use of the pit Phil managed to fit all the new bolts in the brake shaft, after drilling the holes for the split pins. Dave L, Steve T and Tony carried on working on the crinolines that needed fettling. Dave also welded the cladding sheet that had to be altered so there was better access to the lubricating pipework. The rest of the lads were working in the boiler shop prepping the water tank for this late afternoons session of riveting.

Saturday 10th August.

Dave Mc, Jack K, Jacob L, Peter M, Richard O, Simon B, Steve M, Steve T, Tony H.

All work was in the Boilershop, including welding and preparing the three back plates for the right hand tank to be welded or riveting on. The overflow pipe at the front of the tank was put aside to have gaskets made so it is ready to be fitted.

Monday 12th August.

Charles L, Dave L, Dave Mc, Jacob L, Peter M, Si B, Steve T, Tony H.

Dave L, Steve, and Tony worked on the firebox cladding sheet that was altered last week. Later They were joined by Peter and retrieved the adjacent cladding sheet from the G.U.V. which is at the far end of the Hollybush siding, we also got the mud hole covers which fit on the two cladding sheets. We fitted the two pieces of cladding and we were satisfied they fitted correctly, we took them off so the lubricating pipework could be fitted.Meanwhile everyone else was working in the boiler shop prepping and painting for the next session of riveting later this evening, and also tomorrow late afternoon.

Saturday 17th August.

No work today as a lot of the gang were on holiday.

Monday 19th August.

Bob L, Bryn T, Charles L, Dave Mc, Peter D, Peter M, Steve T, Tony H.

Again, most of the work was done in the boiler shop prepping the water tank for the next riveting session, and also welding. We did manage to look at the left-hand water tank that is fitted to the loco regarding the rear balance pipe where some of the bolts securing it to the tank do not line up. More fettling is needed. We also checked the dimensions on the chimney to make sure our figures were correct before we ordered the steel plate that fits to the copper cap. PS following the riveting session this evening, all the riveting on the tank is complete. An excellent achievement by all concerned.

Saturday 24th August. No work today.

Monday 26th August

Charles L, Dave Mc, Jack K, Steve M, Steve T, Tony H.

All the work was concentrated on the water tank, Jack was welding the inside seams in the water tank. Steve T was also welding and prepping the parts that are welded to the bottom of the baffles and stretchers that are inside the water tank. The rest of us were fitting the large pipe that runs vertically through the tank. The water feed from the injectors to the clacks, run through this pipe, the same as the previous tank. We also fitted the rear back panel. This will be welded on in the next few weeks. Steve also welded the three bolts to the bottom of the overflow pipe. Steve M was touching up the scratched paintwork on the loco.

Saturday 31st August.

Dave Mc, Kevin S, Steve M, Tony H.

The large pipe that runs vertically through the tank was fitted to its correct position at the base of the tank, the top plate along with the reinforcing ring that is riveted on was fitted, marked and cut to the correct length. This is ready to be welded on Monday. The rear back plate was removed in readiness for welding the strengthening pieces to the bottom of the baffles inside the tank, again this will be done next week.

Tuesday 13th.

Dave Mc, Steve T, Phil D, Jack K, and Pete M on site in the evening. We bolted the backplate on at the cab end and we then made a start riveting it in place. We completed the row of 30, 3/8” rivets.

Tuesday 20th.

Dave Mc, Bob L, Phil D, and Jack K completed the riveting on the driver’s side tank, 42 x 5/8” rivets were successfully installed. The next stage of the project is to complete the welding.

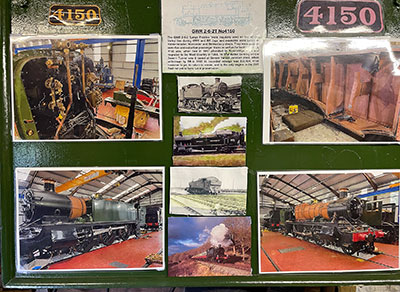

The fund display boards has had a refresh, here it is, first used on our evening special.

A close up of the photo board showing the new photos.

Phil, with the jack, and Jack with the rivet gun at work riveting the top of the tank in place at the cab end. The rest of the team is Dave Mc on heating, Steve T on the jack pump, and me on the camera. I also cut the rivets to length!

The end result of Tuesday’s 13th’s, efforts, all of rivets at the end of the cab completed.

Bob L rubbing down the tool boxes in the pant shop, ready for a new coat of the correct top coat.

Another piece of the pipework jigsaw, this one runs from the steam heat shut off valve to the Masons valve (the Masons valve reduces the steam pressure to a safe level for the coaches).

All the riveting complete, after a huge effort by all the team. Photo Bob Leonard.