August Update

By Peter Maddicks

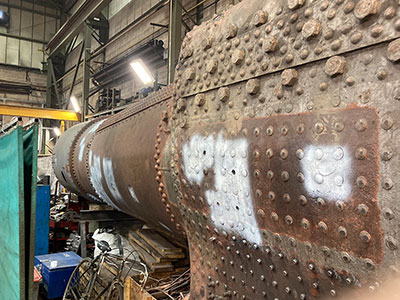

Monday 1st. a very busy day today, six of us in the boiler shop, Peter D, Dave Mc, Tony H, Steve T, Charles L and myself. It was time to start fitting the tubes. All the tubes are ordered 2” longer as the tube plates are not completely flat, therefore you have to take the distance between the outside of the two tube plates and add 3/4”, that is 3/8” each end. By the end of the day we had cut and fitted 79 tubes, they will not be expanded until all have been installed. Peter and I would first move the tube from rack, put the one end in the chop saw and the other end will go on the stand. We then measure it and Peter cut it to length. Tony and Steve then take it over to the smokebox end of the boiler, feed it in to Charles who puts the tube in the correct hole, (you start at the bottom, work out and up). Dave was in the firebox, Charles pushed the tube in, then Dave pushed a bar through correct hole and Charles then pushed the tube into the tube plate. Dave then put on a 3/8” gauge to set it in the right place, Charles does the same at the smokebox end, we then adjust the length of the next tube if necessary. By the end of the day 79 tubes installed, not bad for the first day.

Saturday 6th. No work on the loco today.

Monday 8th. I was not on site today, so thank you Tony for the information.

Bryn T, Charles L, Dave Mc, Si B, Steve T and Tony H on site today, all in the boiler shop on tube fitting duties. By the end of the day 105 tubes fitted, only 34 to go!

Saturday, 13th. No work today, boiler shop closed.

Monday 25th. I was not on site again today, so thank you again Tony for the information. Charles L, Dave Mc, Steve T and Tony H in the boiler shop, fitting the final 34 tubes. The next job will be the flue tubes, once they are in we can start expanding them.

Saturday 20th. No work today.

Monday 22nd. Today the team was Tony H, Charles L, Dave Mc, Phil H, Steve T Phil H and myself. The first job of the day was a cup of tea and a catch-up. Then we collected the six flue tubes from storage and moved them into the boiler shop. These tubes are heavy and 12’ long, thank goodness we have low superheating, therefore we only have six to move and fit. Then it was time for lunch. Now that the shed works are all but complete it is time to oil up the loco ready to move back to the yard.

Saturday 27th. Only three today, but a good one, we arrived at Bridgnorth to find the loco and van back in the yard. Therefore the first job of the day was to get the power on in the van and get the kettle on. The next job for Tony H, Simon B and I was to get the access platform, wooden tool box and the front sand gear operating rod from the boiler shop yard. We then removed the tarpaulins from the loco ready for her to go into the shed.

Monday 29th. Bank Holiday, but as we are all retired it does not make much difference. On site was Tony H, Charles L, Steve T and myself. After the compulsory cup of tea we arranged to get the loco on the long pit, thank you to the staff on duty for their help. It was a good day to get on the pit as the full time staff were off. The job for the day was to fit the new spring hanger bolts. The first job was to get four large packing timbers and put two each side at the front of the loco under the buffer beam, then we collect two 25t. jacks and place on top of the timbers. We then jack up the loco, as soon as the nuts on the top of the spring hanger bolts are loose we remove the nuts and extract the old spring hanger and fit the new one. We do this one at a time, once the new one is in and the nut is on we then fit a half nut. As soon as we have done the front half of the loco we moved the jacks to the rear and we then finished the last six hangers. The final job on the loco was to adjust the pony truck. We then put the timber’s and jacks away.