August update - part 2

By Pete Maddicks

August has carried on as it started, on Saturday the 14th Simon B was busy welding on the balance pipe reinforcing plates, on the bunker base, assisted by Tony H and Bob L. Steve M was working on the cab roof.

On the Monday Bob L and myself got two coats of red oxide on the cab roof and on the bunker base. Then one coat of chassis black.

Tony H and Charles L were working on the Fruit van, as the roof sheet had blown off the Shrewsbury end. They also got the doors at the Kidderminster end working too. At the end of the day Charles and I removed the rubber rings from the spring hangers, we then made a start on the cleaning of the metal components.

On Saturday the 21st I could not be at Bridgnorth, I thought I had better go to my son’s wedding, I had a feeling I would be in trouble if I went to Bridgnorth! Therefore the information and photos are from Tony Howard.

The first job was to get the pony truck out from under the front of the loco, this is easier said than done, as it is quite a complicated setup, being compensated with the leading driving wheels.

Once the pony was out, the loco could be lifted, the driving wheels and the radial truck could be rolled out. It all sounds easy, but everything is heavy, big and dirty.

I would like to give a big thank you to the boys that worked so hard to get the loco off it’s wheels, well done boys. (See photo 1, boys in front of the the loco, up in the air with the wheels out).

On the following Monday we started on dismantling the pony truck, Bob L cleaned and painted the equalising beam. He then got a coat of undercoat black on the cab roof. Steve T and Charles L removed the Horn ties from under the axle boxes, Tony H and Simon B removed the two protective covers and equalising slide blocks tops, then removed the bottom halves while I was cleaning all the parts, nuts and bolts in the cleaning bosh. Tony H then ran the die-nut down the bolts and a tap through the nuts. We then removed the frame of the pony truck from the wheels and axle boxes. Simon B drained the oil out of the axle boxes. It was then time to call it a day.

Saturday the 28th we arrived on site to find that the pony axle boxes were off and had been cleaned. Three of us today, Tony H, Simon B and myself. After the mandatory cup of tea, Tony and Simon attempted to get the slide plates off the guide blocks but they broke the impact screwdriver! Therefore it is back to the drawing board. I made a start on removing the LL (left leading) axle box, first removing the cover plate and cleaned out all of the old oil and trimmings. Removed the tee bar, (which allows the springs to be attached to the axle boxes). Next, remove the under keep, (the under keep is a reservoir of the oil and a pad that puts the oil on the journal).

The reasons we have had to lift the loco off it’s wheels is that the pads are old, hard and enough oil will not pass through to keep the journal’s oiled when the loco is under load. Also some of the oil ways are blocked. A lifting eye is then screwed into the top of the axle box and the crane is then hooked on, the box is lifted off and transferred to the bosh. Tony and Simon then give all the parts a good clean. Then put the the box back together and put it on a pallet.

From left to right, the team that lifted the loco off it’s wheels. Kevin Seabridge, Simon Beeston, Dave MaFall, Tony Howard, Ian Bromley, Les Bromley, Dave Fulchur-Insull.

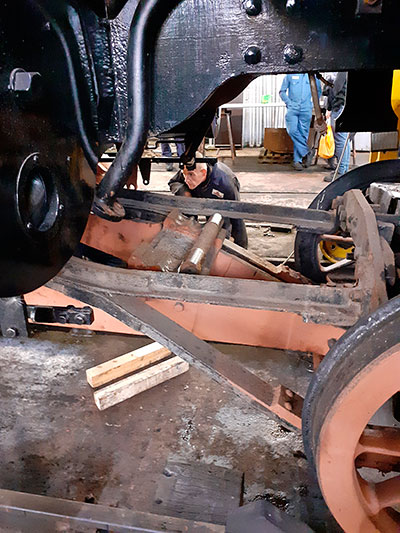

As the jacks are slowly lifted to free up the pony truck, Dave F-I is keeping a close eye to make sure nothing is going to get jammed.

The compensating beam on the floor and the forklift ready to pull the pony truck forward.

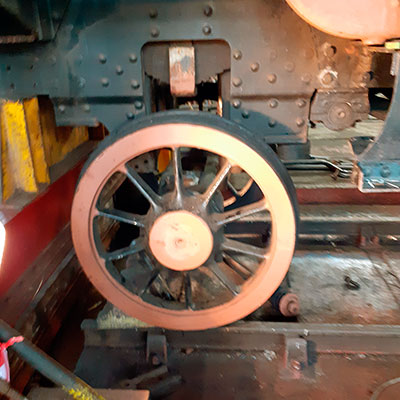

The radial truck is almost out as the jacks move up.

The driving wheels out, but a little more to go to get them out from under the loco.