Restoration update

August 2017

We've been concentrating on fitting the boiler and firebox cladding recently, with the aim of getting it all completed and then removed for painting and storage before the boiler goes down to Bridgnorth for overhaul.

A new perspective, of the tanks, bunker and cab roof in position on the frames.

Cladding in position on the left hand side of the firebox. The expansion plates which enable the firebox to slide slightly on the frames as the boiler expands on heating (it's bolted solidly at the smokebox end) have been removed.

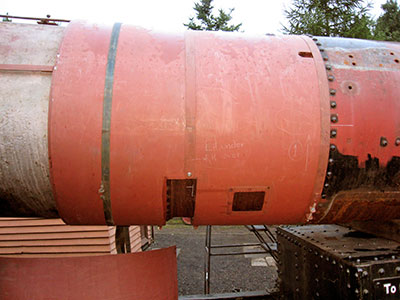

There are four cut-outs in the r.h. front boiler cladding sheet. Clockwise from the top, these are for a wash-out plug (just visible at the top), for the lubrication pipes to the smokebox-mounted shut-off cocks, for a cover plate to enable removal of the rocking shaft top cover, and for the large motion bracket which passes beneath and very close to the boiler.

The crinolines on top of the boiler provide a solid base for the central handrail used by firemen when climbing up to fill the water tanks. The end bosses screw into 3/4" tapped holes in a 20mm plate under the cladding.

Holes have been cut to install ferrules around each of the four wash-out plugs in the boiler barrel.

One of the new 'elephant's ears' - cladding which covers the front corners of the firebox - yet to be fitted. Not easy to make!

The saddle which supports the safety valve bonnet in position. Small plates have been welded to the underside, into which holes will be tapped for the bonnet's 1/2" brass slotted securing screws.

A new battery box has been fabricated for attachment to the left hand tank inside the cab.

New buffer step treads have been adapted and re-profiled to fit the front buffers. The rear ones are in sufficiently good condition not to need replacement. Photos: John Whitcomb