April 2024 update

By Pete Maddicks and Tony Howard

Lots of progress again this month, but again I have missed most of it. I am hoping to be back to normal next month. I did manage to get to Bridgnorth, get a few photos and Tony as well as his usual report has sent me some photos. The first photo this month is the beautiful little loco Fenchurch from the Bluebell Railway. It was parked on the long pit outside our van. We are hoping to run a special evening train from Kidderminster to Bridgnorth, we will be able to take groups into the works so you can see the progress of yourself. More information next month, hope to see you there. Now over to Tony for the update.

Monday 1st April.

Bob L, Charles L, Dave Mc, Gary M, Phil H, Steve M, Steve T Tony H.

Work was mainly in the boiler shop. Dave flatted the paintwork on the back of all the plates for the water tanks. Bob then gave them all a final coat of Rustoleum. Tony, Charles and Steve T looked at bolting the bracket that supports the float arm for the water gauge. We found it needed some fettling to fit. Tony shortened the width on the bandsaw. It just needs a little more work to miss the rivets. Phil and Gary carried on work on the stuffing boxes. Dave, using his skills at operating the Crane lifted the chimney onto the smokebox ready for next week's open house weekend. Steve M painted the advertising board, again for the open house weekend.

Saturday 6th April.

Dave Mc, Peter D, Steve M, Tony H.

This weekend is Open House Weekend where members of the public have access to the Machine shop, Locomotive Shed and Yard. Steve was giving an update on the progress of 4150’s restoration. Dave and Tony were in the boiler shop fettling and fitting the bracket that holds the float arm for the water gauge. Once fitted they were joined by Peter and the second large back plate was fitted to the left-hand water tank. We had fitted the first one last week, and it fitted quite well it did not quite fit the profile of the baffles. In the week Phil D Boilersmith modified the fixings and it fitted the profile a lot better. It looks like we will have to do the same operation on this one. All the riveting on the left-hand tank is now done.

Monday 8th April.

Charles L, Dave Mc, Peter D, Steve T, Tony H.

Yes, we did have to do the same operation that was done last week. A few more bolts had to be fitted to pull the back plate into the correct position. All preparation work was done for welding. The two lifting eyes were bolted on the tank ready to turn it onto its front.

Saturday 13th April.

Dave Mc, Kevin S, Simon B, Steve M, Steve T, Tony H, Jack K and Richard O, new working member.

Since the return to steam of 4930 Hagley Hall, there has been a problem with its tender brakes. Earlier in the week its brake cylinder was removed and stripped down to find the cause of this problem. It was found that the I R (India Rubber) sealing band had been incorrectly fitted. As our brake cylinder had a new I R band fitted around the same time, we were asked to check ours. Kevin, Simon and Tony took on the task of removing the brake cylinder from 4150. With Dave operating the Crane we got the brake cylinder out and onto a pallet. We were then joined by Steve T and the brake cylinder was stripped down. We found our I R band was fitted correctly. The cylinder was put back together and is ready to go back into the loco on Monday.

Meanwhile in the boiler shop welding the back plates on the water tank continues by Jack, Richard and Steve T.

Monday 15th April.

Bob L, Charles L, Dave Mc, Gary M, Peter D, Peter M, Phil H, Steve T, Tony H.

It was decided not to put the brake cylinder back into the loco until it was tested. This gave Bob a chance the give it a coat of chassis black all over. Tony with Peter M operating the Crane put the large floor plate back in place to cover the large hole in the cab area where the brake cylinder sat. Two bolts were fitted to secure it. A pallet was also placed to cover where the vacuum reservoir sat. Gary and Phil carried on working on the Driver's side Stuffing box. In the boiler shop more welding and cutting the heads off the securing bolts so welding around them could take place.

Saturday 20th April.

No work today.

Week 22nd April

Work continues on the stuffing boxes, and also in the boiler shop on the left-hand tank.

Saturday 27th April.

Dave Mc, Jacob L, Jack K, Richard O, Tony H.

Today's job was to fit the water gauge arm and float and rod, then weld the two top plates. First, the water gauge arm was bolted in position, but it did not look right. After some head scratching we realised that the bracket that was fitted a few weeks ago was in the wrong way round. We rectified the bracket and everything fitted correctly and lined up. The two top plates were prepared for welding and bolted in position along with the lifting eyes. By the end of the day, both plates were 50% welded on.

Monday 29th April

Bob L, Bryn T, Dave Mc, Gary M, Phil H, Peter D, Peter M, Steve T, Tony H.

The beading that fits on the top of the water tanks was prepared for painting. The back of the tank was painted. The 6mm rivets we have for fixing the beading had somehow got rusty although only surface rust. Tony took them home as he has some rust remover chemicals. The vacuum cylinder was put back onto the loco and will be tested next week. Peter D was looking at various pipe fittings and acquired drawings for the ones we need. Phil and Gary carried on working on the stuffing boxes.

Fenchurch outside our van on the Saturday of the Gala. The Bluebell keeps this little loco immaculate.

A small jig made by Phil D to help the riveting!

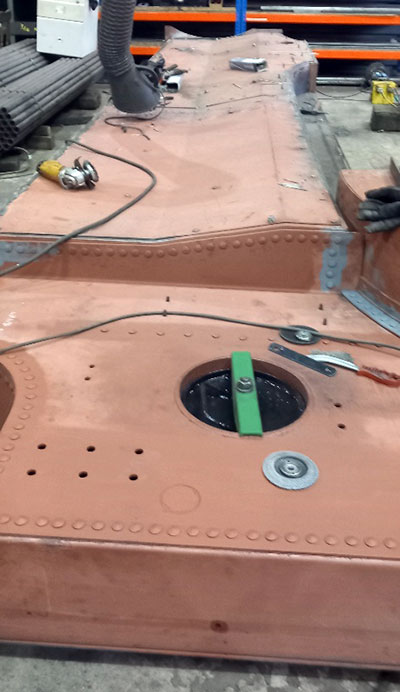

The back of the fireman’s side tank with all the welding complete and ready for painting.

Drivers side steam pipe stuffing box complete and ready to be fitted to the new steam pipe when it is delivered.

Gary starting on the fireman’s side steam pipe stuffing box. Phil is on the inside of the smoker box.

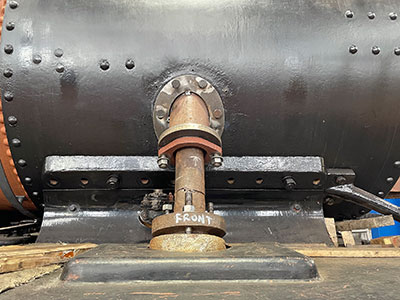

The door that seals the access hole temporarily fitted to check the neoprene seal was adequate. Photo Tony H.

Tony H and Peter D temporarily fitting the top rail to the top of the tank to check it all the holes line up and the messer up a small insert to be welded in to finish off the front of the tank.